中文

ZM Series Alumina fusion cast refractories are produced with highly purified alumina raw material which is melted at high temperatures of more than 2000℃ in an electric arc furnace and then allowed to cool and solidify in a mold. The products contain almost no matrix glassy phase, hence exhibit excellent minimal contamination to molten glass.

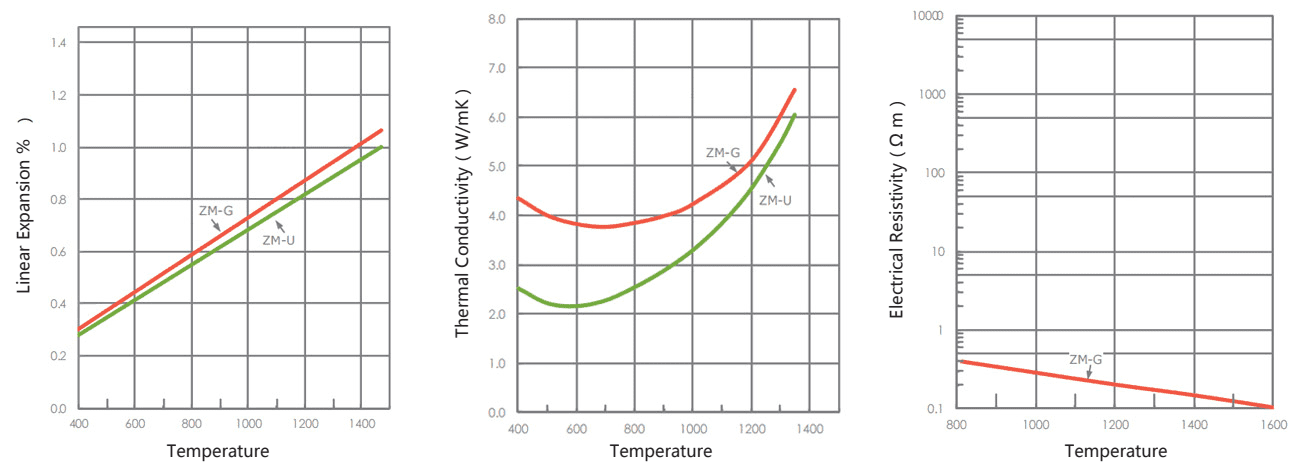

ZM-G products are composed of α-alumina and β-alumina. They form a very sophisticated structure, excellent resistance to alkali and resistance to corrosion.

It has superior characteristic of non-contamination of molten glass with extremely low blistering.

ZM-G products are suitable for Working End Sidewall, Paving, Channel, Canal,Crown etc. in high-quality glass melting furnace.